Two recurring challenges in the day-to-day business of many medical technology companies: Lack of traceability between work items and unnecessary redundancies in the system.

Pain point 1: It’s late afternoon. All requirements of design level 2 have been finalized in a meeting and now “only” need to be linked to the higher-level requirements of design level 1 in the system. Your task. What do you do? You open two lists, one with the Level 2 requirements and one with the Level 1 requirements. Then you make a focused comparison. With any luck, there is a filter in the system that shows the new requirements. Then the tedious, error-prone clicking back and forth begins. And who can guarantee that no assignment has been forgotten or is correct? Nobody.

Pain point 2: A change is due, but you know that this information is maintained in several places in the system. Where exactly? How do you find all the relevant occurrences? And how do you make sure that the outdated version is no longer active anywhere?

In this blog post, we present three Orcanos features that address exactly this issue: System Tables, Work Item List Automation and Advance Automation Rules. They bring structure and automation to your processes, reduce redundancies and ensure that information can be reused and found reliably throughout the system.

Instead of having to maintain content multiple times, as with Word documents, information is stored centrally in the system. The functions described here make this data automatically available in all relevant places – no copy & paste, no transfer errors. You always work with consistent documentation.

Best of all, traceability is fully automated. Manual links between work items? Not necessary.

System Tables

Purpose

In many digital management systems, system tables are created statically. They are configured by the administrator and can be used as selections in drop-down menus, similar to Excel spreadsheets. Static system tables make it possible to provide predefined information as choices that can be used in custom fields.

These tables can be used as controlled selection aids to standardize input and minimize error sources through free text input. Orcanos automatically assigns a status table to these selection fields. As the name suggests, these tables are static, i.e. their selection options cannot be changed by interactions or other data. If the tables are to be changed or extended, this must be done manually by the administrator.

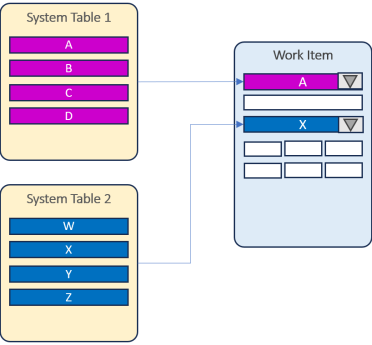

Implementation in Orcanos

The following figure shows how the system tables work: Two tables contain predefined values (A-D) and (W-Z) that can be selected from drop-down menus in the associated custom fields, i.e., assigned to the data object. Initially, the fields are assigned an initial value from the table (e.g., “Not Set”). The data selection can be a single selection or a multiple selection (field type “Text Combo Box” or “Multiselect”). The tables are accessed and only values from the table are available. This allows for consistent, rule-based data entry. This is important if you want to evaluate the data later automatically using database queries, as the terms you are searching for are clearly defined.

On top of this, Orcanos offers two more complex features: Work Item List Automation and Advance Automation Rules, which are described in more detail below.

Conclusion of Static Tables

Static tables provide a clear separation between data management and data entry. They prevent arbitrary entries and ensure structure and consistency. Depending on the field type, both single and multiple selections can be defined and flexibly adapted to the respective requirements. This reduces errors, saves time, and creates a reliable database for automated processes. However, the disadvantage is obvious: the contents of static tables must be defined in advance and do not adapt dynamically to the information status of the database, but must be maintained manually by the system administrator.

Work Item List Automation

Purpose

Work Item List Automation adds dynamic content to the static principle of system tables. While system tables are maintained manually with fixed values, Work Item List Automation creates lists based on the contents of specific work items.

This means that the content of specific work items is automatically collected and transferred to a dynamic list (system table). The lists are automatically updated as data objects are added, deleted, or renamed. This eliminates the need for administrative maintenance of selection values and keeps the database up to date directly from the context of your project data.

Implementation in Orcanos

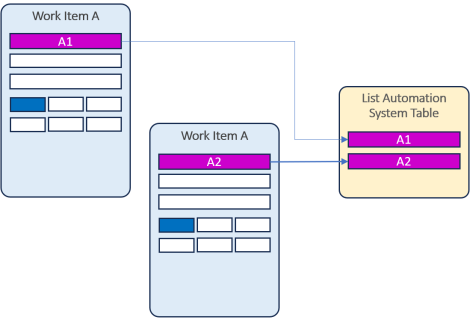

To set up work item list automation, first define the project, the work item type, and up to two of the desired custom fields to be included in the dynamic list with a separator. When a user enters a value in the linked custom field in a work item, that entry is automatically added to the dynamic list.

In the following figure, the custom fields of the Type A work item marked in pink are assigned to a dynamic list using List Automation. When a new work item (e.g. A1) is added, the contents of the field are also automatically added to the linked system table. If another work item (e.g. A2) is created later and the same field is filled, the list is expanded accordingly. This dynamically created system table is then available to other work items as selection information, as already described for the static tables (see Figure “Function of system tables”).

Conclusion of Dynamic Tables

Work Item List Automation is a useful complement to static tables. In addition to the benefits already mentioned, the information can now be dynamically adapted to the current state of the database and is no longer subject to rigid administrative control. It is an ideal solution for constantly evolving project content.

However, this method also requires a certain amount of caution if changes to information are subject to strict change management. Orcanos also offers several options to take reasonable precautions and maintain change management compliance.

Advance Automation Rules

Purpose

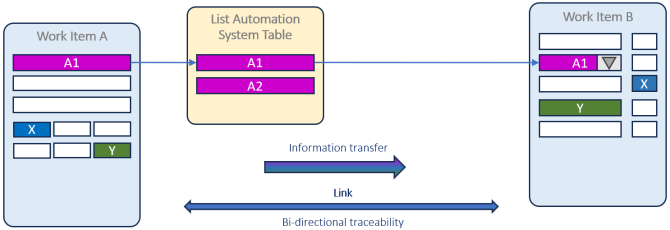

The static and dynamic tables are very useful, but they do not seem to have come much closer to alleviating our pain points described at the beginning, namely the automated linking of work items and the transfer of information units. This is not the case, however, because we have laid the essential foundation with List Automation, which we now want to expand with another building block: the Advance Automation Rule.

Advanced Automation Rules combine two powerful features:

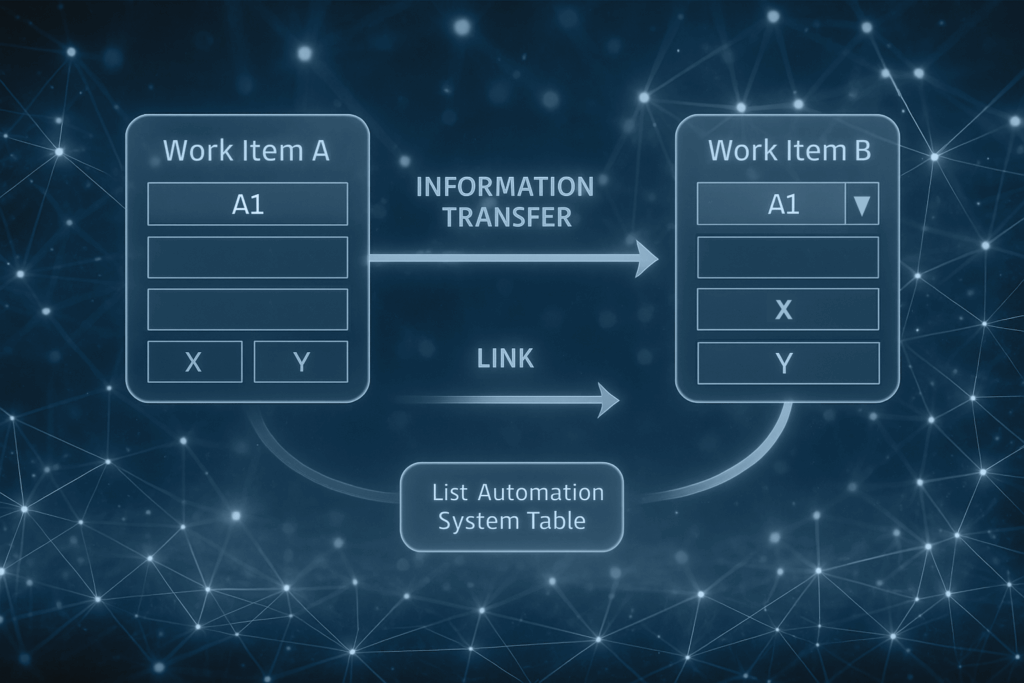

- automatic traceability between work items, and

- Information transfer between related fields.

This means that if you select work item A1 of type A from a dynamic list in a work item of type B, a link is automatically created between the two work items in the database, the type and direction of which you can define yourself. You no longer need to do this manually.

Data objects are now often linked because their contents have some meaning to each other. For example, a harm object in which you define the harm and its severity can be associated with a particular risk. It would be tedious if you had to click on the corresponding link every time you wanted to access information about the corresponding extent of damage. For this reason, Orcanos allows you to define a matrix in the Advanced Automation Rules that transfers the information from the data fields of work item type A to the fields of work item type B.

Implementation in Orcanos

The configuration requires a few preliminary steps:

- Create a dynamic list of the data object to be linked (here work item A) with the Work Item List Automation.

- Define a selection field in work item B that accesses the dynamic table of work item A.

- Call the Advanced Automation rule:

- Define the link type between the two work items

- Define the matrix of a desired data transfer.

When transferring data, make sure that the data fields of the receiving item are of the same type as the transferring item. This is especially true for list elements that access dynamic or static tables.

Conclusion of Advance Automation Rules

The greatest added value is the fully automated traceability. Simply selecting a single piece of information from a list field creates the relational data structure in the background. This means less effort for you and the possibility to enter even more relations. This gives you many advantages for later evaluations and analyses. In addition, automatic data transfer allows you to maintain information centrally and use it consistently throughout the system. This eliminates redundancy and ensures that information is always available where you need it.

This feature is especially useful for complex change processes. Changes made at one central point automatically affect all relevant points – quickly, securely and traceably. This not only simplifies change management, but also makes it much easier to prepare for audits and reviews.

As you have already noticed, this method can be used to create a 1:n data structure if the workflows are designed so that the structures are always created using the “consuming” work items. With good planning, this is very often successful. This way, clean data trees are created and circular connections within the database are avoided.

Final Conclusion

Time pressures, complex requirements and high regulatory hurdles are the reality for many medical device companies. This is why it is so important to use systems that do not complicate processes, but simplify them without compromising quality. This is where the three Orcanos features presented in our article come into play.

System Tables create clear structures and prevent input errors thanks to standardized selection fields. Work Item List Automation significantly reduces administrative effort by generating dynamic lists directly from the system. And with the Advance Automation Rules, not only the manual linking of work items is no longer necessary, but also the transfer of data between linked elements is fully automated.

In short: Orcanos helps you to concentrate on the essential – the content work. Its features not only reduce your workload, but also prevent errors and create a structured, traceable and scalable documentation environment.

At the same time, they provide additional value by greatly simplifying the maintenance of your data, and the standardization and sophistication of the data structures created open up new possibilities in the world of digital data analysis. Welcome to your digital future!